More process reliability during system circuit diagram changes

Changing digitally with the system

Hannover, |

at this year's international suppliers fair for the automotive industry, IZB, the Hanover-based software system supplier Aucotec AG will be introducing its new change management for the harness design development process. A core issue is digital change documentation which significantly improves comprehensibility and process reliability.

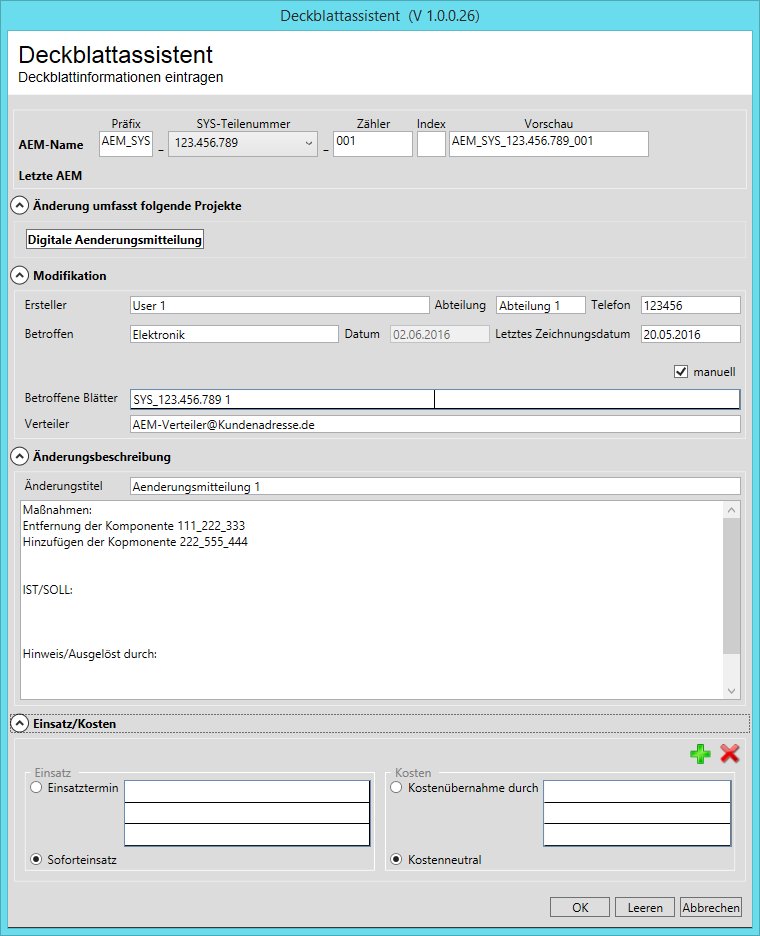

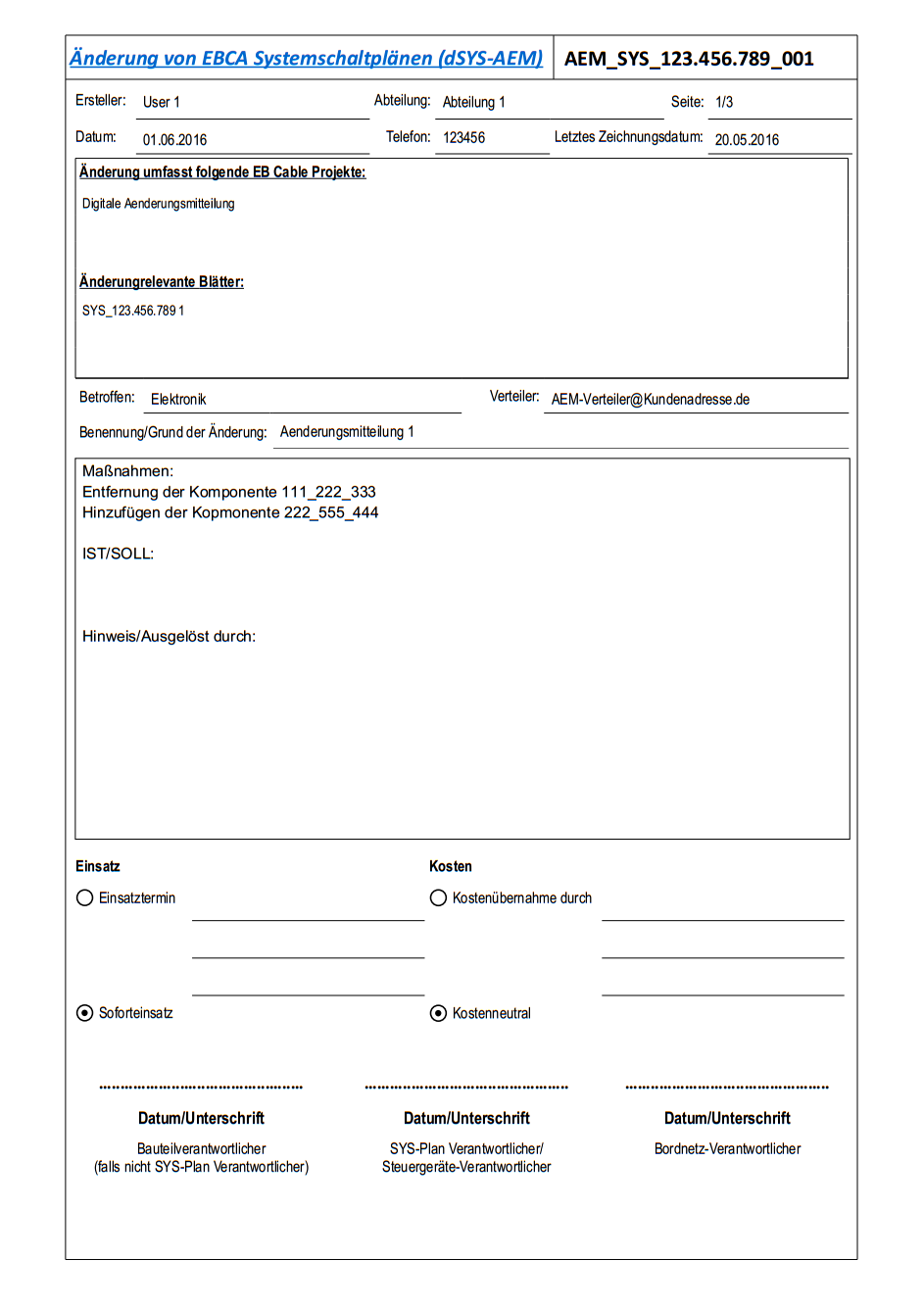

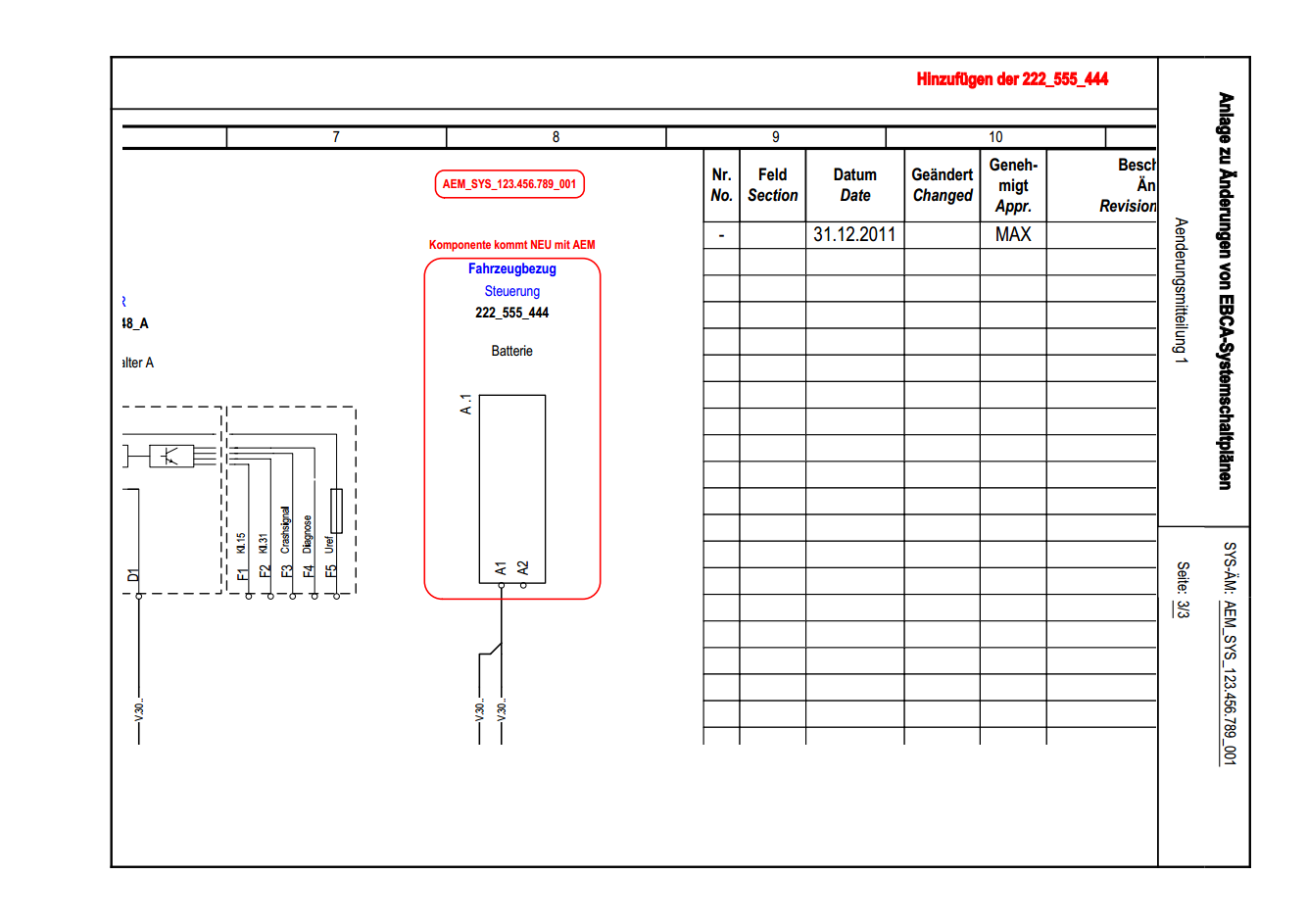

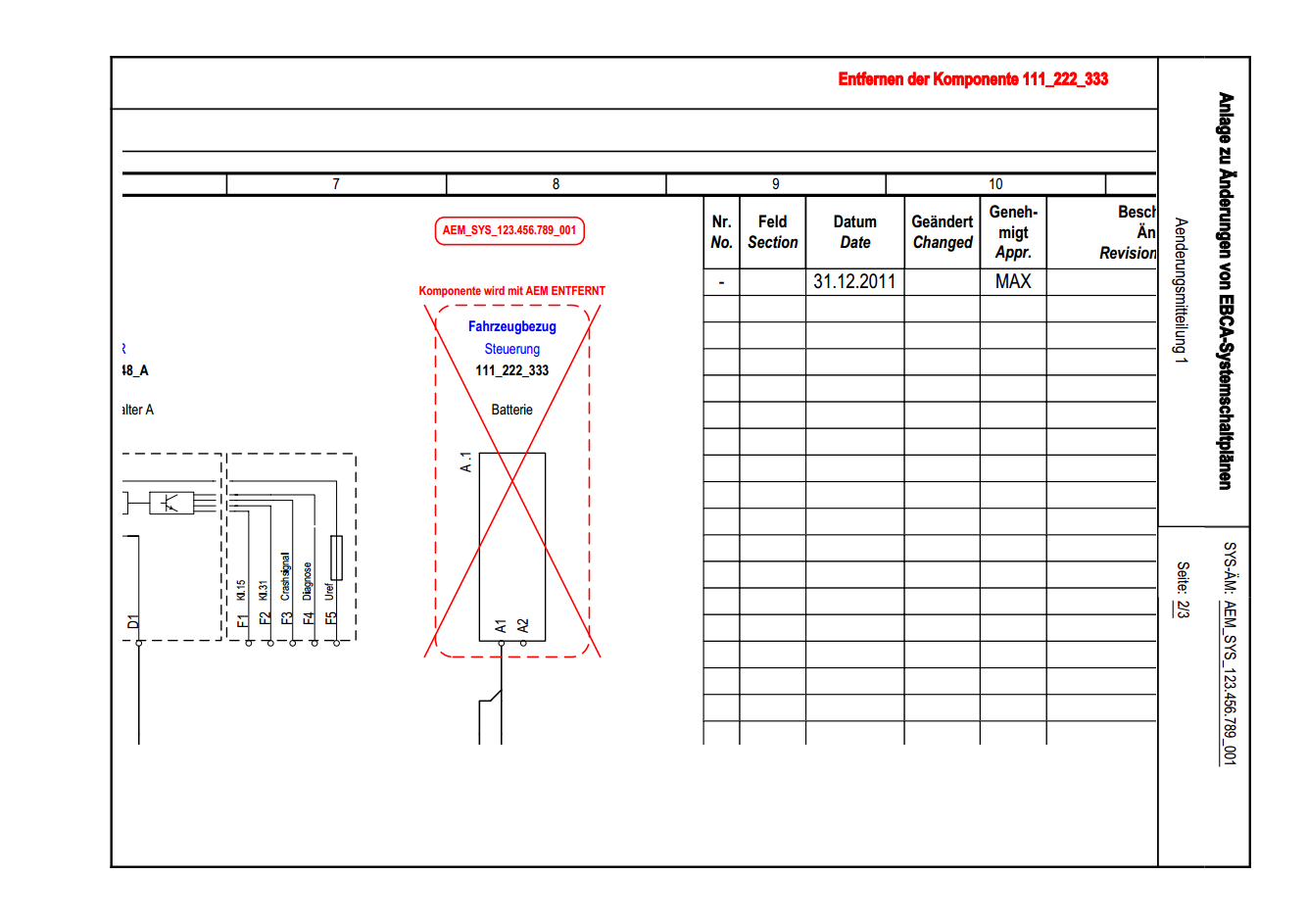

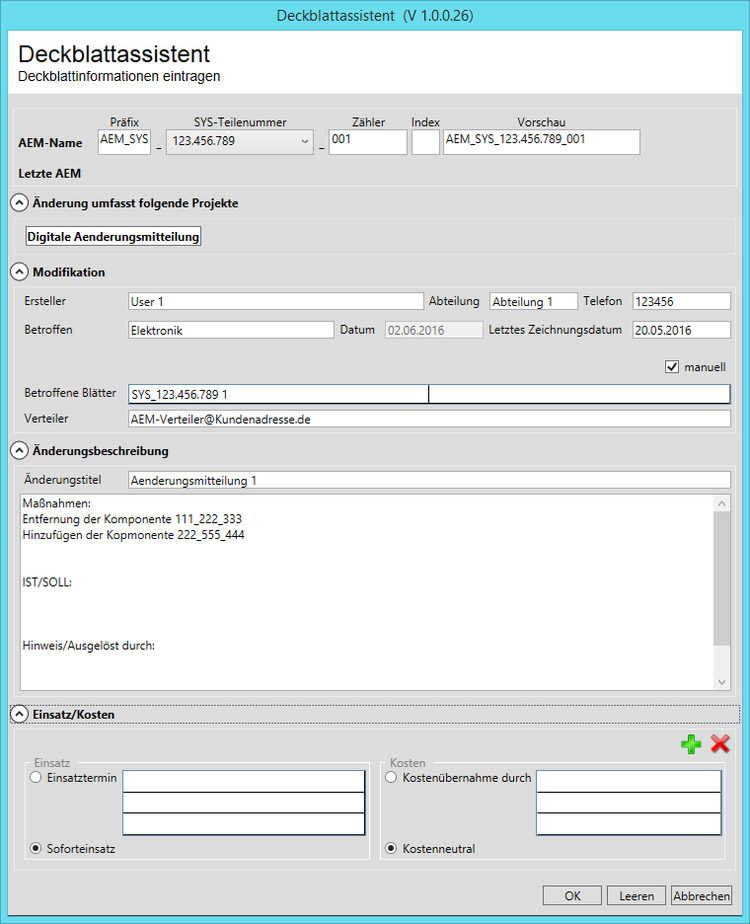

Designers must implement the inevitable changes made to the superordinate system circuit diagram (SYS plan) of a vehicle during the ongoing development process in the actual wiring diagram (KAB plan), which provides specific detailed about wires, plugs, splices, etc. to production. Instead of the usual manual change sketches and time-consuming discussions, corrections and changes can now be made in change mode and forwarded digitally just by clicking. The documentation contains administrative information, for example, date and those responsible and, if necessary, snapshots of the modified parts of drawings with changes marked. It also enables a clear "before" and "after" comparison to be made.

The new procedure, which is significantly more efficient and more correct, is also an essential precursor to the next step, which will allow the direct importing of changes into the KAB plan. Aucotec's developers are already working on this next step.

Aucotec at IZB Fair 2016: booth 3501, hall 3